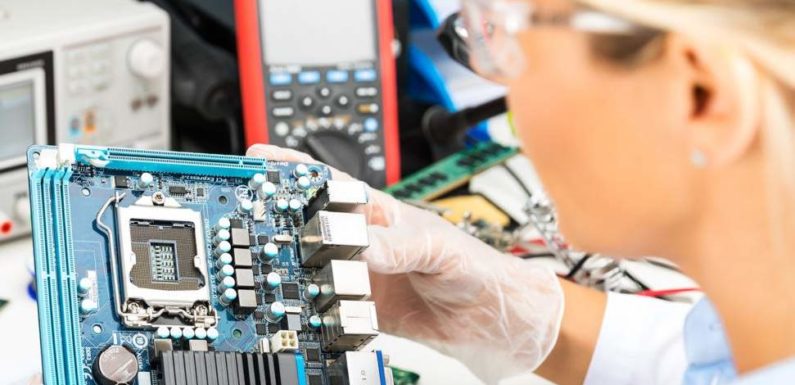

Technological innovation is advancing at a staggering rate, and EMS businesses are working hard to keep up with the prevailing trends, integrate new technologies themselves, meet the ever-increasing customer demands, all the while tending to meticulous cost control across the board for a more financially stable future.

Yes, with every trend and opportunity in the EMS industry comes a challenge that businesses need to analyze and eventually overcome in order to stay relevant in the competitive marketplace. With that in mind, here are the five trends that currently dominate the electronics manufacturing field that will reshape the future of the industry.

Green electronics manufacturing is on the rise

The challenge of meeting environmental standards and lowering the impact of device manufacturing, assembly, transportation, as well as the impact that the devices itself have on the environment is paramount. As countries around the globe are enforcing strict preservation and conservation legislation in hopes of decreasing green gas emissions and hindering the progress of global warming and climate change, EMS businesses are finding new ways to cut energy consumption across the board.

Not only is reducing energy consumption important for the environment, but it benefits the business as well by aiding cost control. Moreover, this leads to a positive trend that emphasizes the need for businesses and consumers to choose energy-efficient devices instead of their obsolete counterparts. The pressure manufacturers are experiencing can lead to positive changes in society, and benefit the industry as well as the consumer market.

The never-ending rise of smart electronics manufacturing

Smart technology has become an inextricable part of our reality, and it is set to dominate the near and far future in every aspect of human existence. As we are barely scratching the surface of the potential of smart technology by manufacturing crude AI-driven smartphones and software, the demand for smart devices is on a constant rise.

From smart electronics in smartphones, personal computers, vehicles, and homes, the world stands on the verge of unprecedented levels of global connectivity. This means that manufacturers are starting to partner up with tech innovators who can aid the production of smart devices that boast seamless connectivity between each other. For instance, by focusing on consumer demands, manufacturers can sense the urgency for innovation and seamless integration of smart technology in mature products such as TVs and laptops.

Healthcare continues to thrive with EMS

Aside from the military industry, the medical field has always been one of the biggest proponents of technology and its integration into every aspect of its operations. This trend is on a steady rise currently as well, as the healthcare industry is always in need of a reliable electronics manufacturer such as M&M Qualtech with a forward-thinking strategy to deliver on the needs and expectations of medical staff and patients alike.

Improving patient care while reducing medical costs is the core strategy of the medical field, and EMS businesses are at the forefront of this struggle. From ensuring high quality and reliability, to being the key partners in the lifecycle of a product, EMS companies are invaluable to the medical industry.

Cost control with long-term strategic partnerships

The technology equipment manufacturing field is constantly evolving, and subsequently, as technological advancements become more refined, controlling manufacturing costs becomes a challenge. This is why original equipment manufacturers (OEMs) are starting to partner up with EMS companies in order to outsource product design and development in hopes of cutting costs and stabilizing cash flow.

What this means for their EMS partners is that now these businesses have the opportunity to venture into new markets, thus opening new opportunities in terms of growth and revenue. This is why, in recent years, the industry has seen a surge in strategic partnerships, with EMS companies offering new lines of services ranging from design to product testing.

Manufacturers are expected to reduce delivery times

The timeframe for product delivery from inception to completion is shortening with each passing year, and currently, manufacturers are expected to expedite the entire process for what is now called “rapid delivery”. Rapid delivery entails the use of logistics systems to effectuate faster delivery times for select customers.

For the foreseeable future, delivery speed will play a vital role in the survival of EMS businesses across the globe, as customer expectations are increasing and product life cycles are decreasing due to tech innovation trends.

The electronics manufacturing industry is evolving at a fast rate in hopes of keeping up with the demands set by the consumers, investors, and technology innovators of the world. These five trends highlight the need for EMS businesses to introduce new tactics and business solutions in order to stay relevant in the competitive industry.